Pesquisa

Com a crescente demanda por eficiência e segurança nos processos industriais, o MVA da Movequip surge como uma solução inovadora para a movimentação de Big Bags. Equipado com tecnologia avançada, o dispositivo oferece aumento de velocidade no processo em até 15 vezes , redução significativa nos custos operacionais e redução expressiva da necessidade de mão de obra. Além disso, ele garante níveis superiores de segurança operacional. Com baterias de lítio e sistema Plug and Play, o MVA combina automação, agilidade e confiabilidade para transformar suas operações.

Sua aplicação é ideal para operações que envolvem armazenamento, carregamento e alimentação de processos com Big Bags. Em ambientes industriais, como armazéns e fábricas, o MVA otimiza o manuseio de materiais, melhora a alimentação de processos automatizados e reduz riscos associados à manipulação manual.

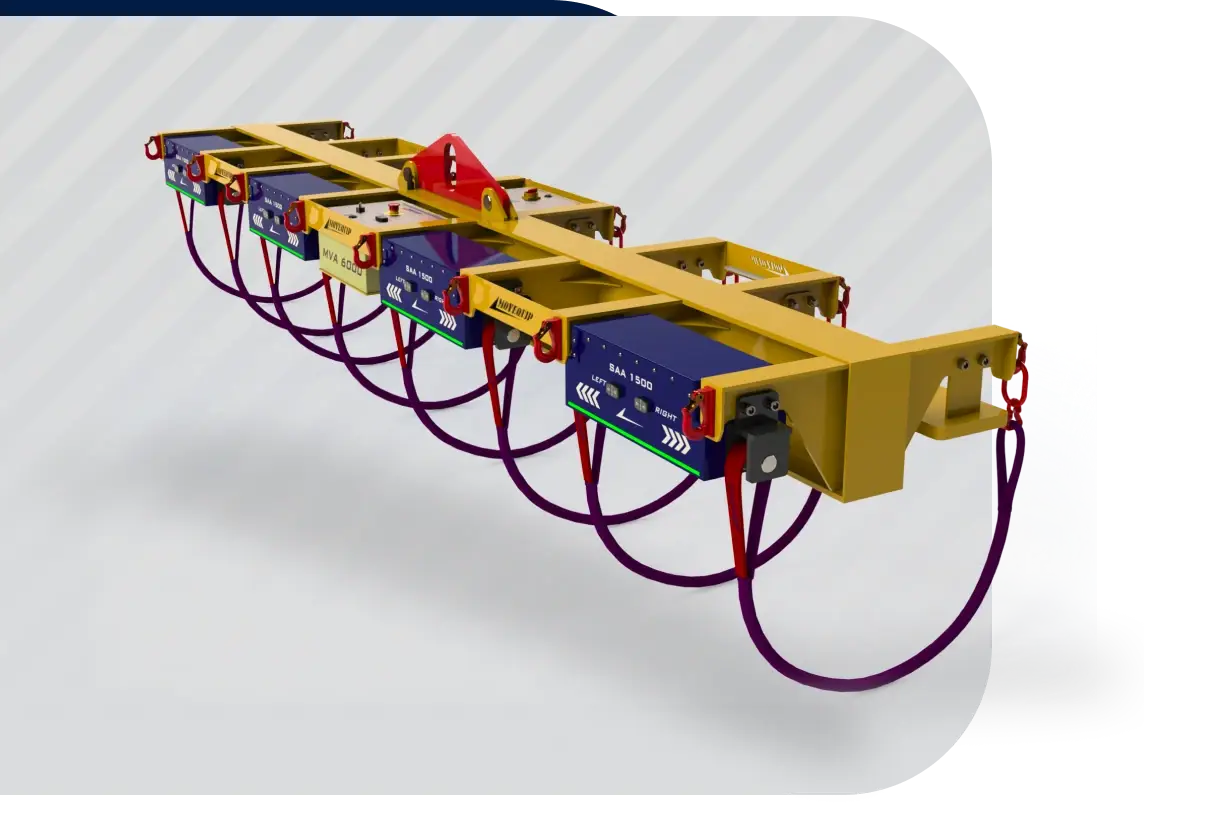

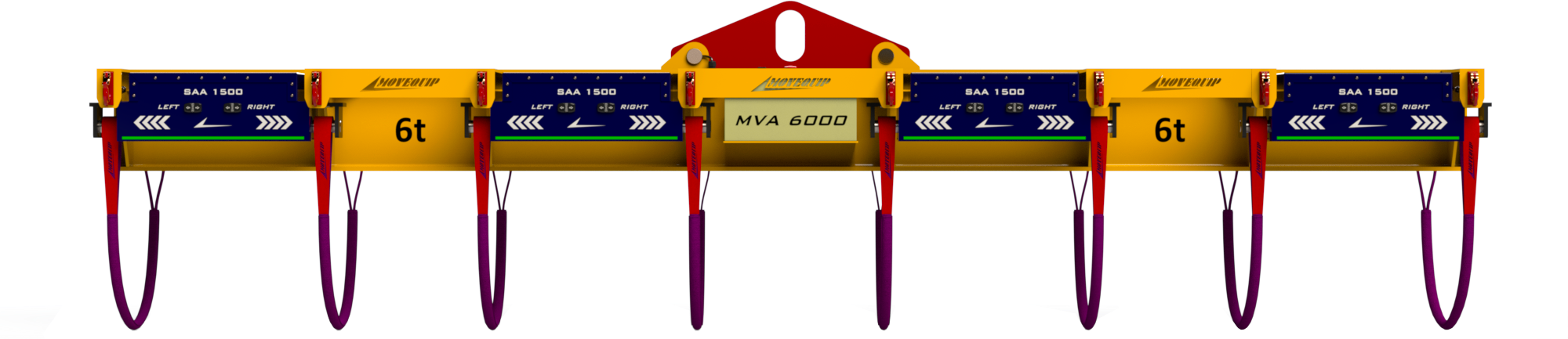

O MVA é um dispositivo robusto, fabricado com uma estrutura de aço capaz de suportar o peso dos Big Bags. O processo de fabricação da estrutura envolve o tratamento superficial das vigas por jateamento, atingindo o padrão SA 2,5, além de um rigoroso controle de qualidade nos procedimentos de soldagem. A estrutura recebe uma pintura especial de poliuretano, garantindo maior durabilidade e resistência. Utilizamos acessórios padrão grau 8 com fator de segurança de 4:1, assegurando um nível de qualidade excepcional.

Após a conclusão da estrutura, incorporamos o sistema SAA (Sistema de Abertura Automático), um projeto mecânico altamente eficiente que atende a todas as normas de segurança. O controle das funções é realizado por um CLP, elevando o desempenho do dispositivo. Além disso, utilizamos lingas especiais e um sistema de ímã de neodímio para posicionar as cintas durante a amarração dos Big Bags. Isso permite que o operador se afaste da carga e realize a operação de fechamento de forma segura e sem preocupações.

Nosso sistema possui motorredutor individual de acionamento, permitindo a fixação rápida e segura das cintas de poliéster imantadas. As demarcações específicas de ancoragem garantem uma operação intuitiva, evitando erros e aumentando a velocidade do processo.

Após posicionar as alças imantadas nos respectivos SAAs, o operador realiza o fechamento dos eixos principais por meio do Rádio Controle, utilizando uma sequência diferenciada entre fechamento e abertura. Esse procedimento garante a prevenção de falhas acidentais durante o manuseio. Invista na inovação e eficiência do seu processo de carregamento e armazenagem de Big Bags.

Descubra a linha completa de dispositivos MVA da Movequip, personalizados para atender diferentes necessidades industriais. Com tecnologia avançada, aumento de velocidade no processo, redução de custos operacionais e segurança máxima, cada modelo oferece soluções personalizadas para movimentação de Big Bags com eficiência e confiabilidade.

Basta preencher um formulário e enviar sua mensagem.

Que em breve retornaremos o contato com mais informações.