Get an accurate diagnosis of the real state of your equipment

If you are the owner or manager of an industry, you know how essential it is to guarantee the safety of workers and the efficiency of the equipment used in the production process. An effective way to achieve these goals is through regular inspection and maintenance of industrial equipment. In this context, we present the V-Zero Inspection, a specialized service that offers a detailed and careful analysis of the equipment, guaranteeing its proper functioning and avoiding accidents and losses.

Industrial maintenance inspection is a highly specialized service, requiring specific equipment and instruments, as well as trained technicians to perform the job with excellence. When hiring a company to perform this service, it is essential to verify its qualification and competence, to guarantee reliable results.

During the industrial inspection process, several procedures are performed to identify possible failures and damage to equipment. The main procedures are: Identification of visible or invisible faults, such as cracks, gaps, wear and unwanted vibrations; Evaluation of pulleys and belts; Quality inspection of the measuring instruments used.

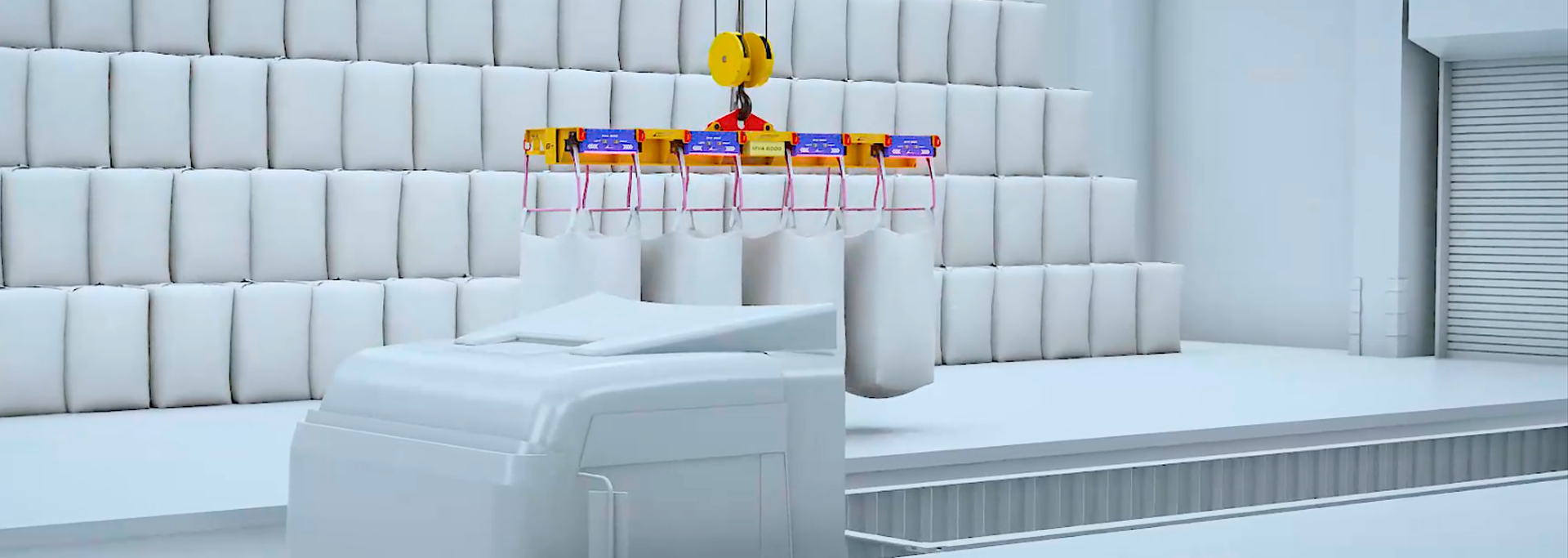

Movequip's V-Zero Inspection is a comprehensive inspection method that aims to keep industrial production optimized. With the help of MIVA, we use 4.0 technology to generate a complete photographic report of the real state of the equipment.

Watch the video and learn a little more about our V-Zero Inspection:

Do not jeopardize the safety of your employees and the proper functioning of your industry. invest in Movequip V-Zero Inspection and be sure that your industrial equipment is in perfect conditions of use.