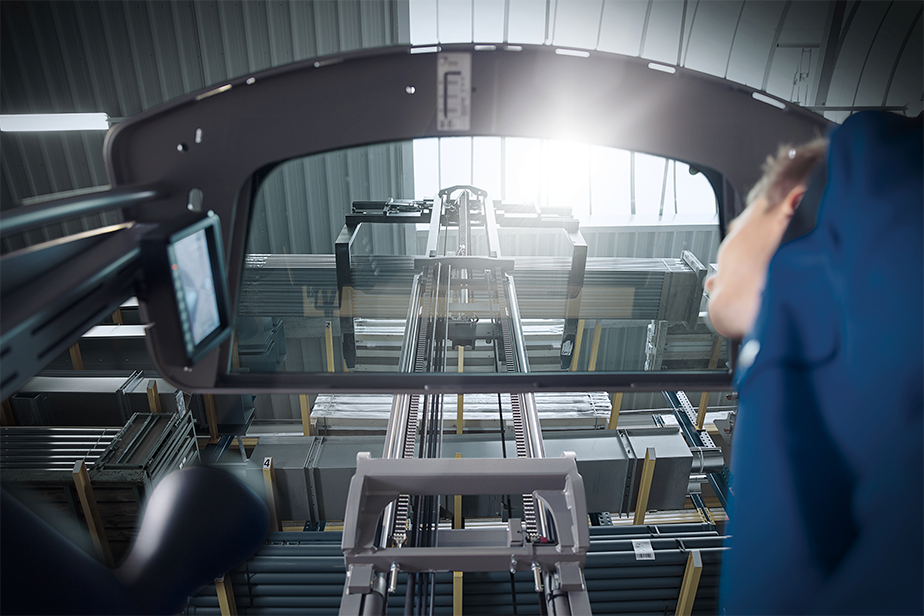

Principle of reach trucks

The reach truck has two strong points: its compact design and its considerable lifting height capacity of up to 13,000mm. When lifting loads, the reach truck pushes its mast forward until the fork is free in front of the truck.

This step is called advancing. Then there is the recoil, which pulls the goods for transport between the front and rear axles. Loads of up to 2.5 t reach their destination quickly and safely with our reach trucks.