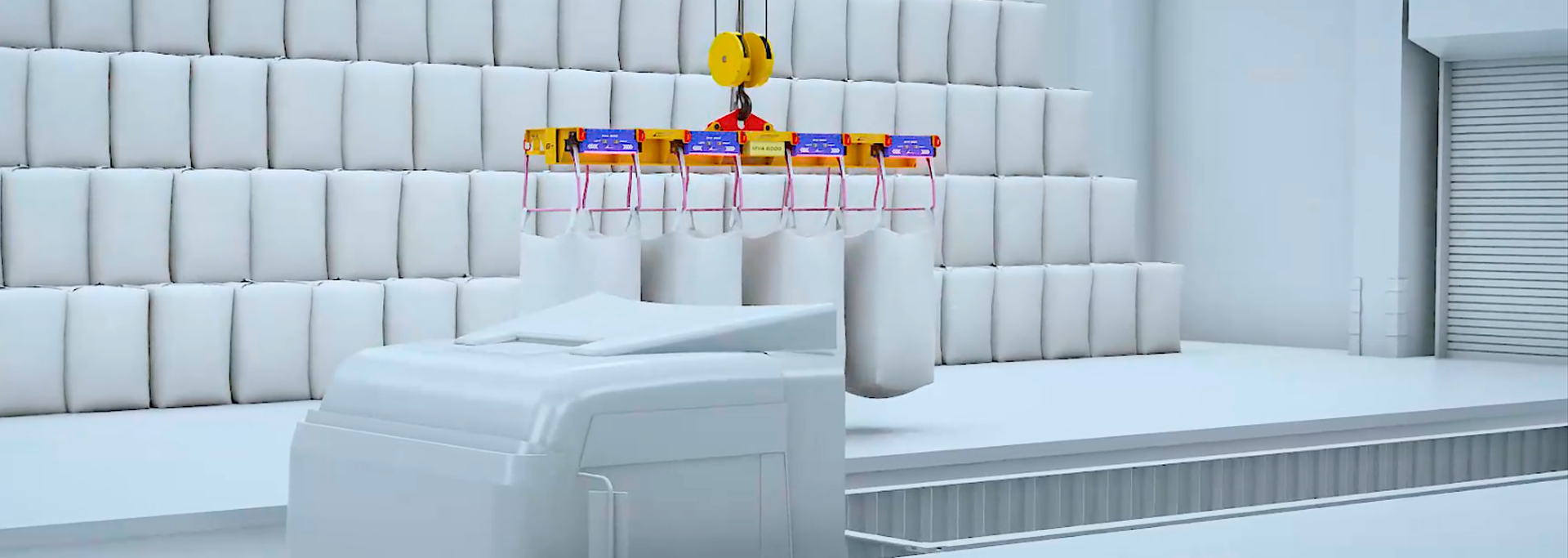

In every industry, the organization of handling equipment processes is fundamental to the success of the operation and results in greater productivity gains. Cargo handling systems must act efficiently, as they are decisive in meeting delivery deadlines.

The cost of inspection is drastically reduced when done on a scheduled basis.

Costs:

The cost of the V-Zero inspection is always lower than the cost of corrective maintenance in unscheduled shutdowns, and can be calculated by adding the following costs:

– Cost of worn or damaged parts to be replaced. Wear and tear that could be avoided with periodic adjustments, adjustments or cleaning;

– Cost of labor to be hired to exchange parts;

– Cost of stopped production; Unscheduled downtime for maintenance, in many cases, is difficult to resolve. In other situations, the solution may be simple, but the resource is not available at the time of occurrence (an imported part, for example). In both cases, the time to solve the problem can be long and cause significant delays in production.

– Cost of employees stopped waiting for the equipment to be repaired;

– Exhaustion with customers due to possible delays.

Conclusion:

Inspection is extremely important for any equipment, as its main objective is to manage resources and maintenance times, eliminating failures and unscheduled equipment downtime.