Is prevention better than repair?

It is very important to pay attention to the productivity and operating time of the equipment (Hoists and Overhead Cranes).

Thus, you will be able to analyze the perfect moment for the inspection to be applied.

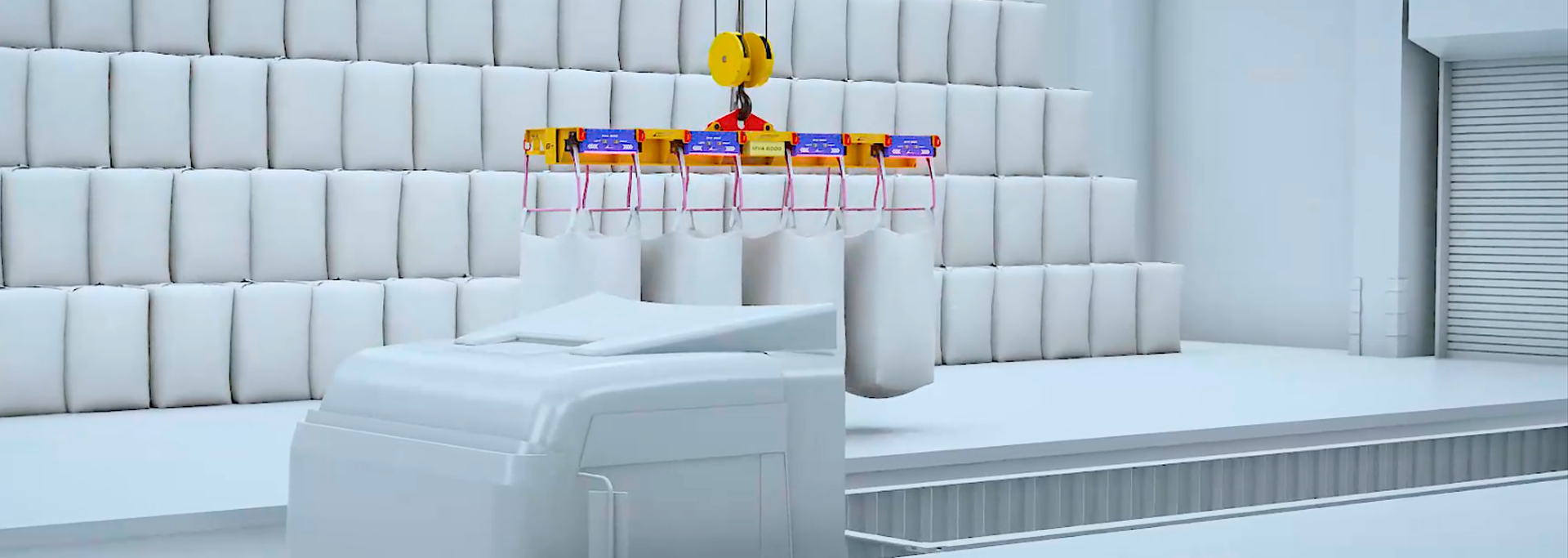

The focus of this article is the advantages of using V-Zero inspection in Hoists and Overhead Cranes.

So, below are some examples of what V-Zero inspection can do in your industrial operation:

– That maintenance can be scheduled for convenient periods.

– Maintenance ensures your equipment continues to run smoothly without the unfortunate surprises of interruption and downtime.

– Unexpected malfunctions and damage always tend to happen at the worst possible time or when the equipment is most demanded.

– To maintain the conservation and useful life of the equipment

– That a complete overhaul of current equipment can expose hidden wear and tear that can be easily remedied by a prior inspection.

– Keeping equipment in good repair reduces the chances of unexpected work stoppage.

– Good maintenance and suitability will provide a safe working area.

Therefore, our suggestion is that you create a policy of regularly reviewing equipment, monitoring metrics and managing equipment. For example, some metrics include time between failures, compliance with the preventive maintenance program and the number of emergency maintenances, these indicators can help to increase the productivity and safety of the equipment.