Lack of preventive inspection are common mistakes that need to be avoided. In this case, the biggest loss is with the company, for not establishing a management plan to define the best time to carry out the interventions.

As a result of a lack of inspection, cranes and electric hoists may fail, which may cause interruption of production processes, unscheduled expenses and increased safety risk.

Check below the 4 main problems caused by the lack of Inspection.

1. Reduction of useful life

Without a quality inspection, wear and tear will only be noticeable when the use of the equipment is already seriously compromised. This will certainly make its maintenance extremely expensive, as the excessive wear of some components such as the brake disc, cable guide, bearings, among others, can damage other components or even the loss of an engine or the whole equipment, in addition to the unavailability of parts or of a qualified technician to carry out the repair in time so as not to harm the process.

2. Damaged processes

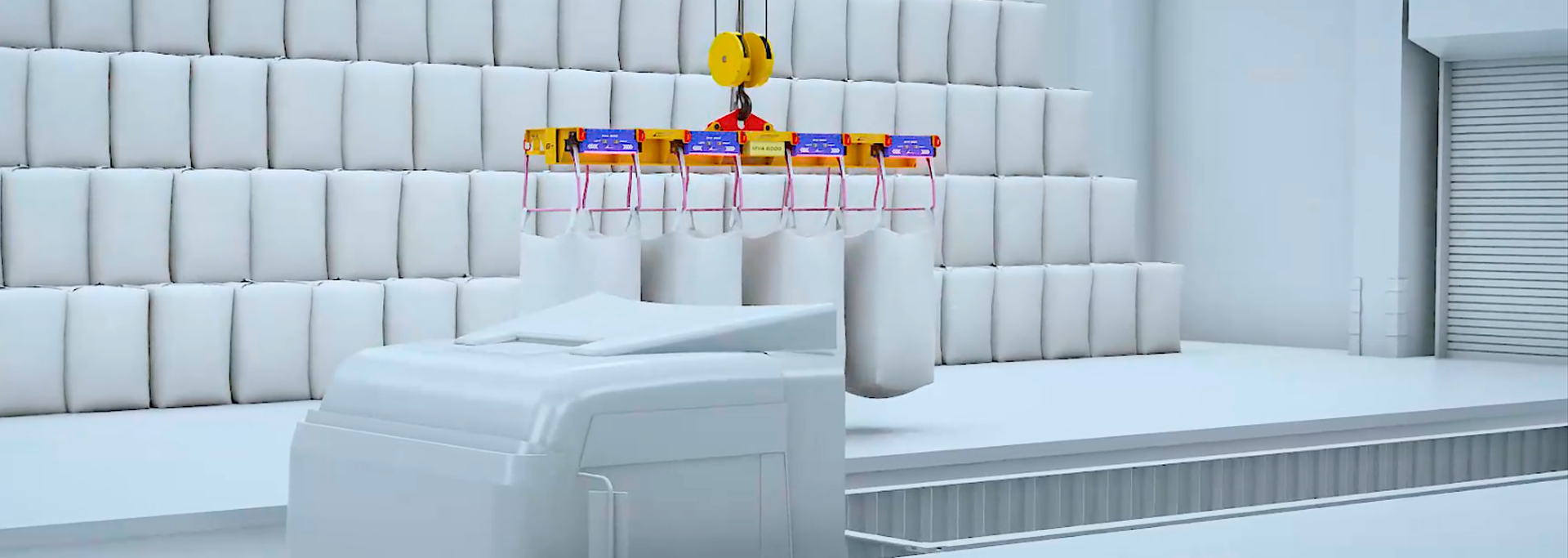

The lack of inspection can seriously compromise industrial processes.

After all, certain defects can lead to loss of efficiency, delays in production, as well as waste of energy and raw materials. That said, there's no doubting the importance of maintenance.

However, more than repairing the equipment or avoiding failures, maintenance must also be carried out in order to improve production processes. After all, we are in the midst of Industry 4.0 and those who do not adapt will lose competitiveness.

3. Increased security risk

Without regular inspection or even without compliance with current safety standards “NR-12”, the equipment can suffer from a series of problems that involve a serious safety risk, such as: Loose parts “that could fall on someone”, failure of brake “which could cause the load to slip”, breakage of a steel cable, contactors sticking, lack of alignment and leveling of the rails “which could cause derailment of the crane”, lack of end stops, lack of safety lock in earnings, etc... All this seriously compromises equipment and safety, putting the physical integrity of employees at risk. Not to mention the sanctions that your factory may suffer for not complying with the standards.

4. Reduced productivity

Without proper maintenance care, the equipment will stop frequently and every time this happens, production will also stop. We don't even need to talk about the damage that this entails, do we?